Who would pay millions of dollars for a vehicle with no steering wheel, seats, or a gas pedal? The U.S. Military, whose unmanned "Crusher" robot can drive itself. This ScienCentral News video explains.

Extreme Off-Roading

Researchers at the

National Robotics Engineering Center, a part of

Carnegie Mellon University, have developed an autonomous off-road military vehicle they've dubbed Crusher. It can travel over extreme terrain, like a 4-foot vertical wall, and can carry up to 8,000 pounds of supplies. All this without any human interaction, using a combination of sensors and artificial intelligence.

John Bares and his team at Carnegie Mellon developed Crusher for the

Defense Advanced Research Projects Agency (DARPA). While some details of its design have not been released, its basic hardware consists of cameras, a GPS receiver, and sensors for motion, balance and monitoring the environment. An on-board computer combines all this information.

"In time actually the vehicle will learn things, like it will learn when it's spinning wheels, it will learn when it's losing stability, and can slowly adapt to try to do better as it moves," says Bares.

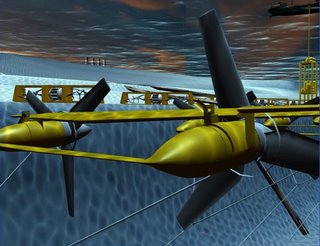

Crusher is one of a growing class of vehicles that can autonomously roam the land, like the recently unveiled

Oshkosh Terramax supply truck; fly through the air, like Boeing's unmanned combat and surveillance aircraft the

X-45; and travel the sea like Sias Patterson's

Fetch autonomous underwater vehicle for coastal surveying.

A main innovation of Crusher is its high mobility. The researchers used a platform that's six-wheel drive, with very large tires, and a very high travel suspension. It also has adaptive ground clearances that can lift it up for navigating steep terrain or lower it down for a low profile.

"When we put all of those together, then we get a vehicle that can keep itself very low to the ground, but go over a tremendous variety of terrain obstacles," Bares says.

As reported on Scientific American online, the ultimate goal is an unmanned surveillance or supply vehicle, or even an automated ambulance.

"Medevac is a great one because that's a very dangerous application and we tend to lose many more troops going in to pull out a fallen soldier," says Bares. "So to be able to take in a vehicle and scoop up and pull out a wounded soldier is great ... and that's also a good application for autonomy, it can be a somewhat slow and deliberate operation."

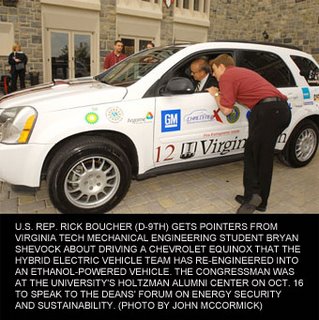

A hybrid-electric engine makes the Crusher able to supply power in the field, as well as to run silently during surveillance operations.

Bares says that while Crusher might have weapons for self-protection, the current goal of the vehicle is to help soldiers in the field with arduous or dangerous tasks.

"I view these kinds of machines are more assisting the troops in the field and protecting them, and helping them many times with the unglamorous tasks, rather than replacing them," says Bares.

There are questions, like: What if Crusher breaks down mid-mission? Does the top speed of 25 miles an hour make it an easy target? And is it any better than a tank or humvee driven by a soldier?

"This vehicle can certainly go places a humvee can't go, and on the other end of the scale an m1 Abrams tank can go a lot of places but weighs 10 times the weight of this vehicle, so I think given its size and its weight, it does pretty well in terrain, and we're trying to make it a little bit better every day," says Bares.

He points out that Crusher is still only a prototype. "Our dream is to make a vehicle that would drive as good as a 14-year-old or something, not even a 16-year-old yet," he says. "So we have a ways to go."

Some question the risk of having robots perform tasks that typically require human intellect and problem-solving skills.

But Bares argues that "very qualified operators fall asleep, or they get tired. So in automated vehicles the hope is that we can improve safety in applications where we put them, but certainly there will always be risk, they are vehicles driven by lots of computers, lots of software, lots of sensors, and they are only as good as how we teach them and how they learn," says Bares. "Right now we have

tractors that can drive in agricultural fields more accurately and in straighter lines than a human operator. So there's certain things that computers and intelligence can do very, very well, but there are other things where we have a long way to go yet."

With the project that created the first two Crushers costing $35 million, they're unlikely to be mass-produced anytime soon. But Bares hopes the technologies developed for the Crusher will also find their way into commercial applications.

"The ultimate goal is to try to advance off-road autonomy to make vehicles that are exceptionally smart and capable as they move off-road and be able to in the future apply that to all kinds of arenas, including commercial arenas, anti-terrorism, rescue response, military, agriculture, construction," says Bares.

The researchers are conducting field experiments of Crusher this summer, and plan to finish it in 2008, when army officials will work with the researchers to test the vehicle on simulated missions.

Recent innovations in Crusher's navigation technology was published in the August 2006 "Proceedings of Robotics: Science and System." More information on Crusher, as well as additional video, was in the May 15, 2006 edition of Sciam.com. Crusher was presented at a DARPA/U.S. Army Presentation of Crusher at Carnegie Mellon on April 28, 2006. Bares' research is funded by the Defense Advanced Research Projects Agency.

Greener News Room

Keywords::

ROBOT, MILITARY, VEHICLES, HYBRID-ELECTRIC, MEDEVAC

It's been 25 years since the start of the AIDS epidemic. In that time the number of those infected with HIV has grown to a staggering 40 million worldwide.

It's been 25 years since the start of the AIDS epidemic. In that time the number of those infected with HIV has grown to a staggering 40 million worldwide.